Ramen Ua Tshuab

Cov tau txais daim ntawv thov

Tsis siv neeg ntau lawm ntawm cov ntawv khob noom cookie thiab ua khob noom cookie Flrocculation Ntau txheej txheej tshiab tshiab noodle

Txheej Txheem Flow

Tsis siv neeg hmoov mov-tsis siv neeg ntsev ua ke, cuble composite-noodle pattration-tsis tu ncua calendering-Sawb THAWJ-SOUND TEEV-NTIM

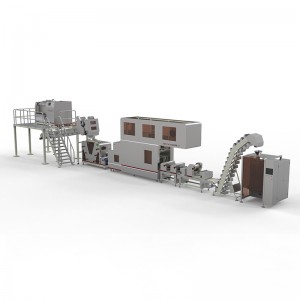

Khoom Taw Qhia

Cov qib ntawm kev siv tshuab yog siab, thiab ua tau zoo yog hais txog yim npaug siab dua li ntawm phau ntawv ua haujlwm.

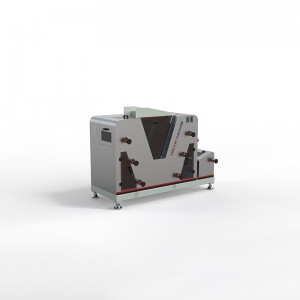

Qog cov tub ntxhais ua koob ua ke, thiab ntxiv dag zog rau cov txheej txheem tseem ceeb ntawm dov thiab tig rov qab los ua cov noodles muaj zog thiab softer.

Modular sib xyaw ntawm cov kab ntau lawm, hloov tau sib xyaw ua ke ntawm cov kab kev teeb tsa ntau dua raws li cov kev xav tau sib txawv.

Ntau-lub ntsiab lus yog soj ntsuam, sib xyaw tswj kev servo thiab zaus hloov dua siab tshiab, tiag tiag synchronous ua haujlwm ntawm tag nrho cov kab, thiab txhim kho kev ruaj khov.

Cov khoom tseem ceeb yog txhua hom khoom lag luam zoo thiab txawv teb chaws, muaj lub neej muaj zog thiab ntev ntev.

Cov ntsiab lus tseem ceeb

Peev Xwm: 600kg hmoov nplej / teev

Lub hwj chim; noodle ua + kom qhuav 200kw

CUA KUB: 0.6-0.7MPA