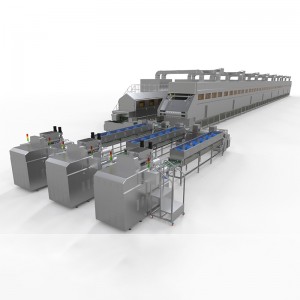

Tsis Siv Neeg Mov Macaroni Cov Kab Ntau Lawm

Tsis Siv Neeg Mov Macaroni Cov Kab Ntau LawmQauv: QzdTXMF-650

Nrog mov raws li cov khoom siv raw ntau, cov ntsiab lus dej ntawm cov txhuv macaroni yog 14-15%, thiab lub txee lub neej tuaj yeem ncav cuag 18 lub hlis.Cov Txheej Txheem Ntau Lawm:

Mov Mov → Rinsing → Rice Sib tsoo → Sharing & Kev Noj → Cov Laus Aging → DRINGING → SUPING DRING → TOFT

Cov ntsiab lus tseem ceeb:

1. Cov khoom lag luam tshwj xeeb: 4mm, 6mm thiab 8mm. Muaj peev xwm ntau lawm yog 750kg / h.

2. 10 teev rau ib qhov chaw ua haujlwm, 8 tus neeg ua haujlwm ib qho hloov pauv, cov txiaj ntsig yog 14t ntawm Rice Macaronis hauv ob qho kev hloov pauv.

Kev Ntsuas Cov Qauv:

| Fai fab hov ntau | 380v |

| Kev Siv Dej | 4t / t nplej mankle |

| Kev siv fais fab | 380 degrees / t nplej mankle |

| Kev Siv Cua Cua | 2.3t / t nplej mankle |

Cov khoom noj mov noj (suav nrog cov nplej ua kom qhuav, ua kom qhuav, cais tawm mus rau hauv cov thawv, kev sib tsoo, ua kom sov, tshuaj tua kab thiab ziab. Nws tau txo qis kev phom sij ntawm kev siv khoom noj khoom haus, txo kev siv zog ua haujlwm thiab txhim kho cov txiaj ntsig nyiaj txiag ntawm cov neeg lag luam. Nws ua rau muaj kev sib tawg hauv kev ua lag luam.

Peb muab cov neeg siv khoom nrog tag nrho cov txheej txheem ntawm turnkey engineering los ntawm cog cov qauv tsim, cov qauv khoom lag luam kev kho kom haum, kev xaiv khoom lag luam thiab muag khoom.